The Significance of Regular Instrument Calibration

Precision is paramount across all industries. Consequently, the accuracy of tools and instruments is non-negotiable. Calibration plays a crucial role in ensuring this accuracy. By comparing instrument performance against established standards, calibration guarantees consistent and precise data collection.

In this blog, we’ll explore what calibration is, why it matters, how frequently pressure gauges and temperature instruments should be calibrated, and why calibration services are indispensable for businesses.

Understanding Calibration

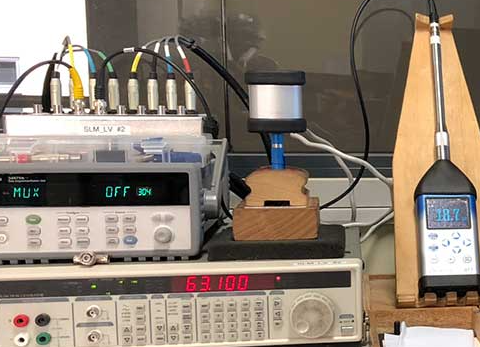

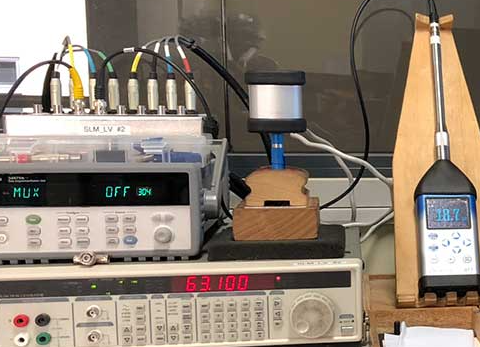

Calibration is the process of adjusting an instrument to ensure its readings align with established standards. Instruments like pressure gauges, temperature sensors, and other measuring tools are exposed to wear and tear over time, which can affect their precision.

Calibration involves comparing the instrument’s output with a reference standard and correcting any deviations. Professional calibration services in Brisbane ensure your tools meet stringent accuracy standards, providing dependable data for operations.

You Might Also Like:

Common Dangers of Not Calibrating Your Equipment

The Importance of Regular Calibration

Regular calibration is more than just a routine; it’s a crucial practice for ensuring efficiency, safety, and compliance in your operations. Here’s why calibration is so vital:

Ensuring Compliance and Consistency

Industries in Australia are bound by strict regulations to maintain accuracy and consistency in measurements. Calibration ensures your instruments comply with industry standards, safeguarding your operations from potential fines or legal challenges. Businesses in Perth, Brisbane, and beyond rely on professional calibration services to meet these demands and maintain consistent performance.

Enhancing Safety

Inaccurate instruments can lead to errors that compromise safety. For instance, an improperly calibrated pressure gauge might provide false readings, resulting in equipment failure or hazardous situations. Regular calibration eliminates such risks, protecting both personnel and equipment. Thus, professional Australian calibration services are essential in mitigating these risks effectively.

Minimising Downtime

Faulty instruments can lead to unexpected breakdowns and interruptions. Downtime not only disrupts operations but also incurs significant costs, which is why calibrating instruments proactively reduces the likelihood of malfunctions, ensuring smooth and continuous workflow. With reliable calibration services in Perth and Brisbane, businesses can minimise these disruptions.

Boosting Customer Satisfaction

Precision in your operations reflects directly on the quality of your products or services. Well-calibrated instruments ensure that your processes yield accurate, high-quality results, keeping customers satisfied and loyal.

When it comes to finding the right service, you need not search extensively for ‘Calibration services near me’; simply call us at +61 (02) 9680 8133

You Might Also Like

Choosing the Right Calibration Service Provider

Know the Frequency of Calibration for Pressure Gauges and Temperature Instruments

The frequency of calibration for pressure gauges and temperature instruments is determined by various factors, including their type, usage intensity, and exposure to environmental conditions.

Pressure Gauges

Pressure gauges play a vital role in maintaining accuracy and ensuring safety in various industrial and commercial applications. As a general guideline, these instruments should be calibrated at least once a year, as regular calibration helps maintain their precision and ensures they perform optimally.

However, specific factors may necessitate more frequent calibration. For instance, if the gauges are used in critical applications where precision is paramount or are frequently exposed to harsh conditions such as extreme temperatures, vibrations, or corrosive environments, their accuracy can deteriorate more quickly. In such cases, increasing the calibration frequency becomes essential to maintain reliability and minimise risks.

Temperature Instruments

Calibration is equally critical for temperature-measuring instruments, including sensors, thermometers, and probes. These instruments typically require calibration every six months to a year, depending on their usage and operating environment. Like pressure gauges, their calibration needs depend on external factors such as environmental conditions, the frequency of use, and the level of accuracy required for the task.

For instance, temperature instruments used in processes with tight tolerances or in environments with fluctuating or extreme temperatures may need more frequent checks to ensure they remain accurate. Regular calibration not only extends the lifespan of these devices but also ensures consistency in temperature readings, which is essential for quality control and safety in many industries.

Consulting professional calibration services near you ensures that your instruments adhere to the recommended calibration intervals and always perform optimally.

Conclusion

Regular calibration is a fundamental aspect of maintaining operational accuracy, safety, and compliance in any industry. It ensures that your instruments deliver reliable results, keeps your processes running smoothly, and protects your business from risks associated with inaccurate measurements.

If you’re looking for dependable calibration services in Perth, Brisbane, or anywhere in Australia, Acu-Vib’s professional calibration services are here to help. Ensure the precision of your instruments today—Call +61 (02) 9680 8133!

Leave a Reply

Want to join the discussion?Feel free to contribute!